There are many different inspections that need to be performed in order to produce high quality perfume bottles. One of the most important steps in the manufacturing process is the inspection stage.

During this stage, a number of different inspections are performed to ensure that the product meets all quality standards.

In this article, we will discuss some of the most important inspections that need to be performed during the manufacturing process of perfume bottles.

I. Different stages of inspection performed during the perfume bottle manufacturing process

a. Raw material inspection

The raw materials used in the manufacture of perfume bottles need to be checked for impurities and defects, and the factory conducts raw material inspection in strict accordance with the technical documents before the raw materials are purchased for size, color, material, etc.

Effectively prevent unqualified products from entering the warehouse to avoid using unqualified products and affecting product quality, affecting the reputation of the enterprise or disrupting the normal production order.

b. Semi-finished product inspection

This stage of inspection is carried out at all stages of the manufacturing process. The factory strictly gates the production process to ensure that the unqualified semi-finished products of each process shall not flow into the next process, to prevent the continued processing of unqualified semi-finished products and batches of semi-finished products are not qualified, it helps to identify any defects or problems that may arise in the manufacturing process to ensure normal production order.

c. Finished product inspection

This is the final stage of inspection and is performed before the product is shipped to the customer. In this stage, all products are checked for any defects or problems. Therefore, from the internal structure of the product to the assembly into a product, vacuum testing is performed on each product. The first pump head leak detection test will be performed on the automated assembly line first, and then to ensure that each product will not have any functional problems when it reaches the customer. In the process of doing printing, there will inevitably be scrap rate, such as printing position shift, incorrect color, dirty and scratched products will be picked out.

II. How to keep quality control during the whole production process

Quality is the life of a company, and it must be kept under control during the manufacturing process of perfume bottles.

The factory has strict quality control for all products, from raw materials incoming, production and processing to the finished products out of the warehouse, they have to go through multiple processes. Each process has special inspectors to monitor the quality of the products throughout the process. Once substandard products are found, they will be dealt with in a timely manner.

Perfume bottle manufacturers generally use traditional quality control methods to ensure product quality, such as sample inspection, process inspection and finished product inspection before mass production. Sample inspection is a method to assess the product quality by testing the samples.

Sample inspection can help perfume bottle manufacturers to identify product quality problems so that they can take appropriate measures to ensure the yield. Process inspection and finished product inspection is a process inspection of the quality of semi-finished and finished products in the production process, and the quality of perfume bottles can be effectively controlled and improved.

These are some effective methods to ensure the quality of products during the production of perfume bottles. By using these methods, manufacturers can reduce the number of defective products and ensure that they meet customer requirements.

III. The importance of using high quality materials in the manufacture of perfume bottles

It is vital to use high quality materials when manufacturing perfume bottles.

- 1. When the material is aluminum, the high quality aluminum ensures that the surface of the casing is smooth and free of pits and pits.

- 2. When the material is plastic, high quality plastic will not be brittle causing it to be easily damaged.

- 3. When the material is glass, high quality glass material is more dense, not easy to break fragile.

IV. How modern technology helps to improve the quality and efficiency of perfume bottle manufacturing

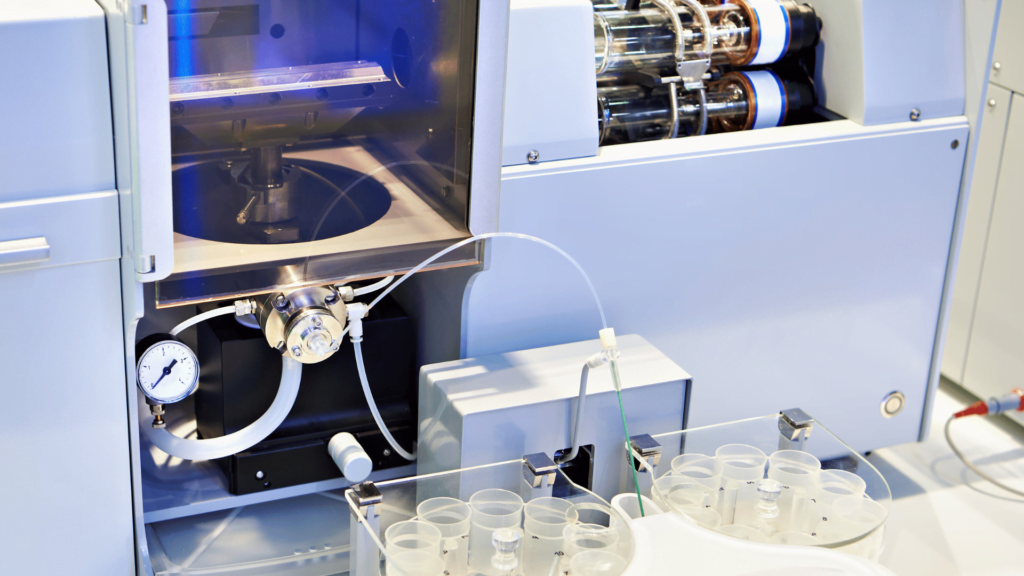

One way that modern technology can help improve the quality and efficiency of perfume bottle manufacturing is to automate some of the testing processes. Automated stamping and polishing technology can allow products to be produced with greater precision and accuracy.

Automated testing machines can perform many of the same tests as a human, but they can do it faster and more accurately, preventing 100 percent of liquid leaks from occurring. This means fewer bottles are eliminated because they don’t meet requirements.

Automated assembly machines can avoid hand marks or scratches on the surface of perfume bottles that come with manual assembly. Another way in which modern technology helps is by providing better quality control.

Through the use of sensors and other devices, manufacturers can collect data about the perfume bottles as they are being produced. This data can be used to identify problems early on and correct them before the bottle is finished.

These are just a few aspects of modern technology that can help improve the quality and efficiency of perfume bottle manufacturing.

As technology continues to evolve, it is likely that more improvements will be made. This is good news for manufacturers and consumers alike. Manufacturers can produce a better product at a lower cost, while consumers can enjoy a higher quality product at a reasonable price. It’s a win-win situation for everyone.

This is an explanation of the various stages of the inspection process for manufacturing perfume bottles and the importance of inspection, which you can discuss together in the comments below the article, thanks for reading!