1–500 Pcs

For Sampling & Market Testing

501–3,000 Pcs

For Branding & Quick Production

3,001–5,000 Pcs

Better Pricing for Growing Demand

5,001–10,000 Pcs

Wholesale Rates & Priority Production

Didn’t find your style or need custom?

Leave a message.

Crafting unique shapes, dimensions, and finishes based on your provided designs.

Techniques including screen printing, hot stamping, anodizing, matte finishes, polishing, and gradient colors.

Providing product renderings or physical samples for pre-production validation.

Covering the entire assembly process—from inner boxes and accessories to outer packaging.

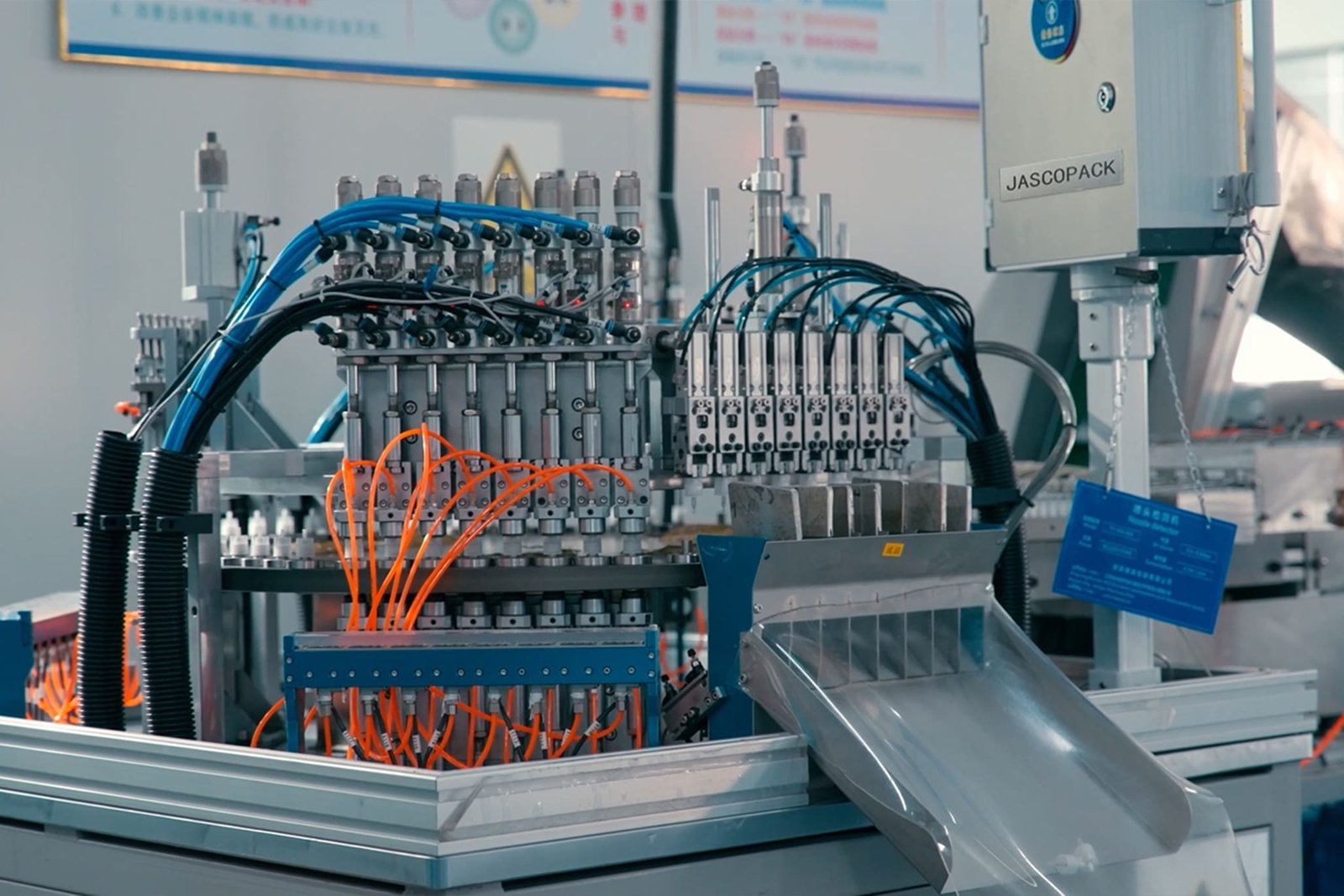

With more than 20 years of production experience, our factory has built a complete and standardized manufacturing system to guarantee stable supply and reliable quality for global clients. We operate advanced injection molding machines that ensure consistent product dimensions, smooth surfaces and durable structure. Automated inspection equipment is integrated into the production line to detect defects in real time and reduce the risk of human error. For components and finished packaging, automated assembly lines further improve accuracy and efficiency.To ensure long-term consistency, a random sampling mechanism is carried out during different stages of production. Every batch is tested based on appearance, sealing, compatibility and functionality. All products are packed in a dust-free workshop to prevent contamination and meet cosmetic-grade hygiene requirements before shipping.Our warehouse is equipped with a complete inventory management system, which supports both large-volume manufacturing and quick delivery for regular orders. At the same time, OEM & ODM services can be connected directly to the production line without affecting lead time. From raw materials to final shipment, every step is traceable and quality-controlled, helping customers reduce risk, shorten procurement cycles and build stronger brand confidence.

High-precision machines ensure consistent shape, thickness and durability.

Real-time defect detection minimizes errors and improves stability.

Efficient assembly guarantees compatibility and production speed.

Products are regularly checked to maintain international quality standards.

Clean environment prevents contamination before shipment.

Organized warehousing supports bulk orders and quick dispatch.

Our Newsletter