The aluminum perfume bottles we often make have various shapes and various colors, so you must be more curious about how these colored aluminum parts are made. Today we will give you an introduction.

I. Stamping of aluminum parts

a. What is stamping

Stamping is a process of forming and decorating metal by pressing it with a die. It is also known as metal embossing.

Stamping includes various processes such as embossing, embossing, flanging, bending, and shallow stretching. The basic steps in the stamping process are blanking, bending and drawing.

Stamping is a cutting operation in which a large amount of pressure is applied to a piece of metal by a die to cut it from a larger piece of metal. Bending is an operation in which the metal is plastically deformed by an external force.

Stretching is a process of stretching a metal blank to increase its length by holding it at both ends and pulling it through a die.

b. What equipment is needed for stamping

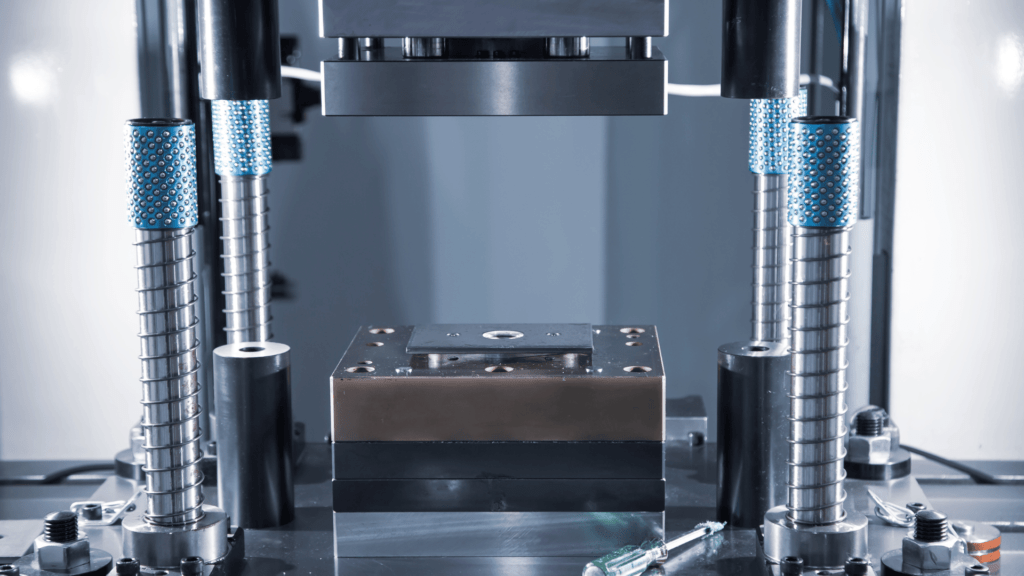

Stamping presses are the main equipment for stamping and various auxiliary equipment such as feeders, straighteners, dies, etc. are also required.

A stamping press is a machine that uses a die to apply pressure to a workpiece to deform it or create a hole in it.

Working Principle of Stamping Machine: When a stamping machine works, the motor drives the flywheel through a reducer and then uses the inertia of the flywheel to drive the crankshaft to rotate.

The connecting rod converts the linear motion of the piston into a rotary motion, which drives the ram up and down along the guide rail.

The die is composed of two parts, upper and lower, where the upper part is fixed while the lower part can be engaged and controlled by gears.

When the upper and lower dies are combined, the pressure moves the punch. When a certain position is reached, the movement of the punch will pass.

c. What to pay attention to in stamping

1. Control the temperature. If the temperature of the metal sheet is too high, it will be easy to produce scratches. If the temperature is too low, the metal sheet will become weak.

2. Pay attention to the stamping speed. If the stamping speed is too fast, the metal sheet will be easy to break; if the stamping speed is too slow, it may produce scratches.

3. Pay attention to the stamping range. If too large, it may cause the metal sheet to break; if too small, the shape will not be completely consistent.

4. Pay attention to the use of lubricant. If the metal sheet is dry, it will be easy to produce scratches; if too much, it will cause the metal sheet to become dirty.

5. Pay attention to the control of stamping time. If it is too long, it may cause the metal sheet to break; if it is too short, the shape will not be completely consistent.

6. Pay attention to cleaning the die. If there are impurities on the metal sheet, it will lead to scratches.

7. Operators pay attention to good protection measures.

II. Polishing of aluminum parts

a. What is polishing

Polishing is a polishing process that produces a shine on the surface of the sheet metal. In the polishing process, the workpiece is usually polished with a grinding wheel, abrasive or polishing agent, and then the workpiece is polished with a cloth or a brush.

b. What are the benefits of polishing

Polishing can give aluminum a bright, shiny surface that can prevent fading. It can also help protect the metal from corrosion and make it easier to clean. Polishing can also add value to a product.

c. What material conditions are needed for polishing

To polish aluminum, you will need a polishing machine, polishing wheels, polishing paste, and polishing molds suitable for the product.

III. Oxidation of aluminum parts

a. What is anodic oxidation?

Anodizing is an electrolytic process that forms a protective oxide layer on the aluminum. The thick oxide layer protects the metal from corrosion and wear, and can be stained to create a decorative surface. Anodizing is often used to improve the durability of parts that will be exposed to harsh conditions, such as outdoor furniture or automotive parts.

b. A few common considerations for oxidation

When stamping and polishing aluminum parts, there are several things you can do to prevent oxidation.

1. Avoid using any cleaners or solvents that contain chlorine. Chlorine is a common element in many industrial cleaners and it can cause corrosion.

2. Use a mild soap and water solution to clean the surface of the aluminum prior to stamping. This will remove any oil or other contaminants that may cause oxidation.

3. Ensure that the surface of the aluminum is completely dry before stamping. Oxidation occurs when moisture is present on the surface of the metal. If you follow these simple tips, you can help prevent oxidation when stamping and polishing aluminum parts.

c. How should I go about controlling the color of the oxidation?

There are a few things you can do to control the color of oxidation.

1. Use a clear coat or sealer on the top of the aluminum. This will help protect the metal from oxygen and other elements that can cause oxidation.

2. A way to control the color of oxidation is to use an anodizing treatment. Anodizing is a process in which a thin layer of oxide is formed on the surface of the metal. This layer can be dyed to create different colors.

3. If you are looking for a specific color, you can also try using bronze solutions. These solutions react with the surface of the metal to create a different color.

In summary, this is the process of stamping and polishing aluminum parts for perfume bottles. You can post comments under the article to discuss together, thanks for reading!